Clutch Kit Completeness Checker

When your clutch starts slipping, grinding, or feeling spongy, you know it’s time for a replacement. But buying a clutch kit isn’t like picking out brake pads-there’s a lot more going on under the hood. A complete clutch kit isn’t just the clutch disc. It’s a system. And if you skip even one part, you risk damaging your flywheel, pressure plate, or even your transmission. So what’s actually inside a full clutch kit? Let’s break it down, part by part, so you know exactly what you’re paying for and why each piece matters.

The Clutch Disc: The Heart of the System

The clutch disc is the component that actually connects and disconnects engine power from the transmission. It’s sandwiched between the flywheel and the pressure plate. Most clutch discs have friction material on both sides, similar to brake pads, and a splined hub that slides onto the transmission input shaft. Some are designed for daily driving with smooth engagement, others for performance with aggressive grip and higher heat tolerance. The material matters-organic, ceramic, or metallic-because it affects how the clutch feels, how long it lasts, and how much chatter you get during engagement.

The Pressure Plate: The Clamping Force

The pressure plate is what squeezes the clutch disc against the flywheel. It’s bolted directly to the flywheel and uses springs to apply constant pressure. There are three main types: diaphragm, coil spring, and Borg & Beck. Most modern cars use a diaphragm pressure plate because it’s lighter, requires less pedal effort, and is more reliable. If you’re upgrading for performance, you might see a heavy-duty diaphragm with stiffer springs. But don’t assume more pressure is better-too much can make your pedal feel like a brick and wear out your throw-out bearing faster.

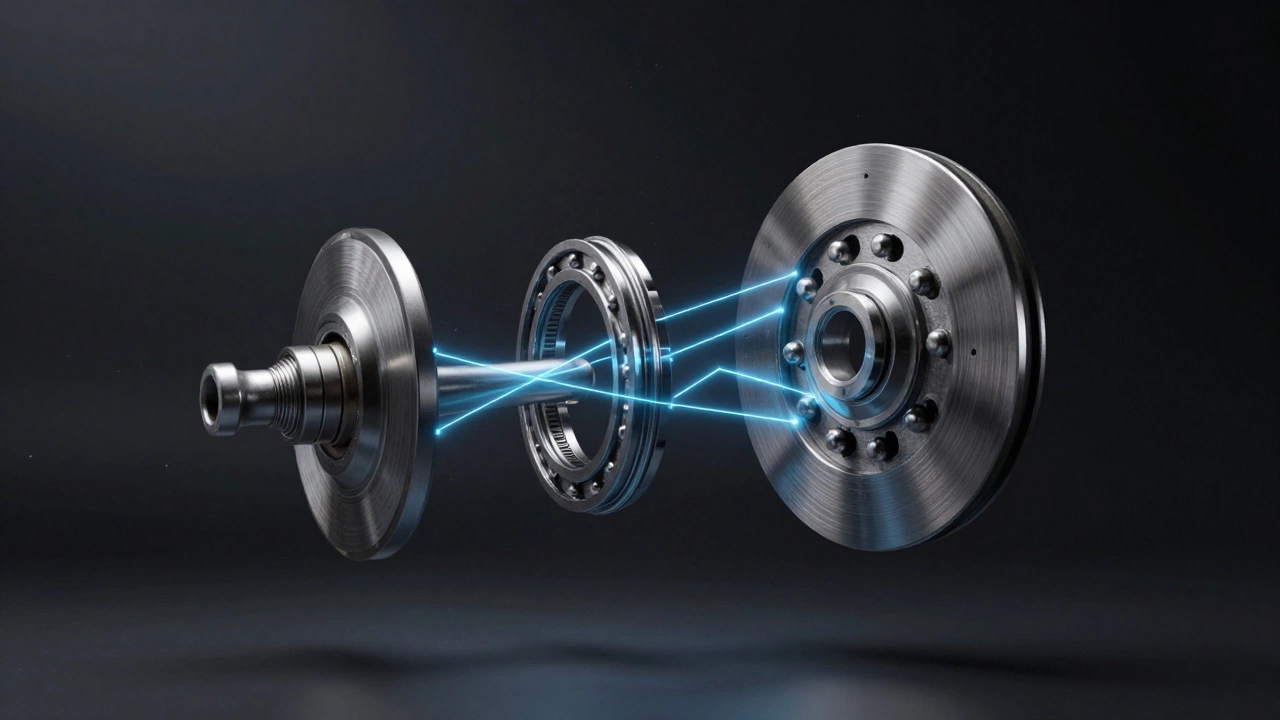

The Release Bearing (Throw-Out Bearing): The Silent Worker

You rarely think about the release bearing, but it’s the one part that moves every time you press the clutch pedal. It sits between the pressure plate’s fingers and the clutch fork. When you push the pedal, the bearing slides forward and pushes on the pressure plate to disengage the clutch. These bearings wear out over time. If you hear a grinding or whining noise when the clutch is depressed, that’s usually the release bearing screaming for replacement. A good clutch kit includes a new one. Never reuse the old one-even if it looks fine. It’s a cheap part that can destroy your entire repair job if it fails later.

The Pilot Bearing or Bushing: Keeping Things Aligned

This small but critical part sits inside the center of the flywheel and supports the end of the transmission input shaft. It keeps the shaft centered as it spins. Older vehicles often use a bronze pilot bearing, while newer ones might have a plastic bushing. If this part wears out, the input shaft wobbles. That causes misalignment, which leads to clutch chatter, gear grinding, or even transmission damage. Many clutch kits include a new pilot bearing. If yours doesn’t, buy one separately. It costs less than $20 but can save you hundreds in repairs down the line.

The Clutch Alignment Tool: Don’t Skip This

Most people don’t realize this, but installing a clutch disc without the right tool is a recipe for disaster. The alignment tool holds the clutch disc perfectly centered between the flywheel and pressure plate while you bolt everything down. If it’s crooked, the disc won’t engage evenly. That means vibration, premature wear, and maybe even broken transmission splines. Some clutch kits come with a simple plastic alignment tool. Others don’t. If yours doesn’t, spend the $10 on one. It’s not optional-it’s essential. I’ve seen too many people try to use a screwdriver or a socket to center the disc. It never ends well.

Hardware: Bolts, Washers, and Springs

A complete clutch kit includes all the hardware you need to reassemble everything: pressure plate bolts, torque-to-yield bolts (if applicable), and sometimes clutch fork pivot ball nuts or return springs. These aren’t just random screws. Torque-to-yield bolts stretch when tightened and must be replaced every time. Reusing them can lead to uneven pressure, clutch slippage, or even a cracked flywheel. Always check the kit contents. If bolts aren’t included, buy a new hardware kit from the manufacturer. It’s not worth risking a $1,200 repair because you saved $15 on bolts.

What’s Often Missing: Flywheel and Slave Cylinder

Here’s where people get tripped up. A complete clutch kit doesn’t include the flywheel or the hydraulic slave cylinder. These are separate components. If your flywheel is cracked, glazed, or warped, you need to replace it. Some shops offer a resurfaced flywheel, but if your car has over 100,000 km, it’s usually better to install a new one. Same with the slave cylinder-if it’s leaking fluid or feels spongy, replace it while you’re in there. You’re already pulling the transmission. Do it right the first time.

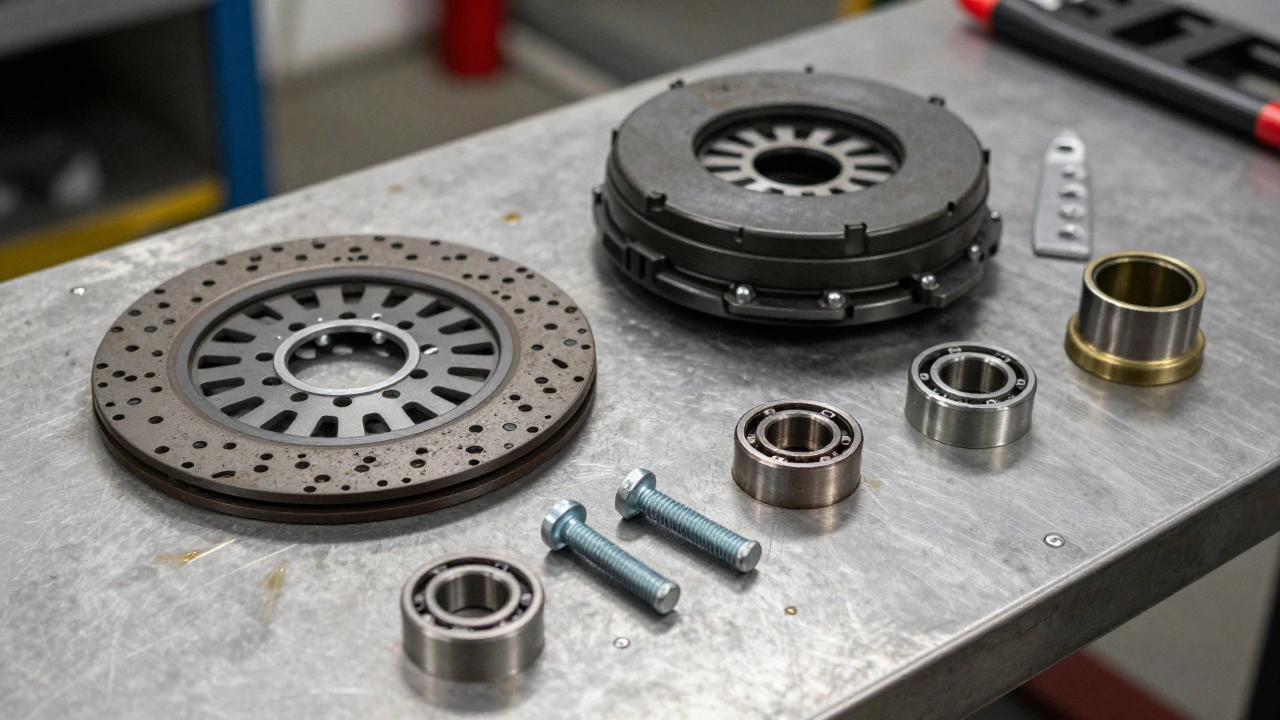

How to Spot a Real Complete Clutch Kit

Not all kits labeled "complete" are actually complete. Some manufacturers sell "clutch kits" that only include the disc and pressure plate. Always check the product description. A true complete clutch kit should list at least these five parts:

- Clutch disc

- Pressure plate

- Release bearing

- Pilot bearing or bushing

- Alignment tool

- Hardware kit (bolts, washers)

Brands like Luk, Sachs, Valeo, and Exedy are known for including all these parts. Budget brands might leave out the pilot bearing or alignment tool to cut costs. Read the fine print. If it says "for select vehicles" or "may not include all hardware," walk away.

What Happens If You Skip a Part?

Skipping the release bearing? You’ll hear noise within 500 km. Missing the pilot bearing? Your gears will grind and the input shaft might snap. Reusing old bolts? You risk uneven pressure and clutch failure under load. Not using an alignment tool? You’ll get vibration so bad you’ll think your engine is falling out. I’ve seen people replace a clutch and then come back two weeks later because they didn’t replace the pilot bearing. The cost of a second repair? $800. The cost of the pilot bearing? $18. That’s not a gamble-it’s just bad planning.

Pro Tip: Match Your Kit to Your Driving Style

Don’t just grab the cheapest kit. If you tow trailers, haul gear, or drive in stop-and-go traffic, go for a heavy-duty organic or ceramic disc. They handle heat better and last longer under load. If you’re just commuting or doing weekend drives, a standard OEM-style kit is fine. Performance kits with metallic discs are great for track days but are noisy, harsh on daily driving, and wear out flywheels faster. Choose based on how you use your car-not what looks cool on a forum.

Final Checklist Before You Buy

- Does the kit include the clutch disc, pressure plate, release bearing, pilot bearing, alignment tool, and hardware?

- Is the part number compatible with your exact make, model, year, and engine?

- Does it specify OEM-equivalent or performance-grade?

- Are torque-to-yield bolts included (if your car uses them)?

- Does the seller offer a warranty? (Good kits come with 1-2 years)

Buying a clutch kit isn’t about saving money. It’s about avoiding a repeat job. A full kit might cost $400 instead of $250, but you’ll save $600 in labor and avoid a week of downtime. Do it right once-and you’ll never have to ask this question again.

What’s the difference between a clutch kit and a clutch assembly?

There’s no real difference. "Clutch assembly" is just another term for a clutch kit. Both refer to the set of parts that replace the worn clutch system. Some manufacturers use "assembly" to imply it’s a pre-assembled unit, but in practice, you’ll still need to install each component yourself. Always check what’s included in the box.

Can I reuse my old flywheel?

Only if it’s in perfect condition. Look for cracks, deep grooves, discoloration from overheating, or warping. If your clutch failed because of heat or abuse, the flywheel likely took damage too. Most mechanics recommend replacing it on vehicles with over 100,000 km. Resurfacing is an option, but it reduces the flywheel’s thickness, which can affect clutch engagement and balance.

Do I need to replace the clutch slave cylinder?

Not always, but it’s smart to replace it when you’re doing a clutch job. The slave cylinder is exposed to the same heat and vibration as the clutch. If it’s leaking fluid, feels spongy, or is over 8 years old, replace it. It’s a cheap part to swap while the transmission is out. Waiting until it fails means you’ll be back in the shop again soon.

Why does my clutch feel stiff after replacing the kit?

A stiff pedal usually means you installed a performance pressure plate with stiffer springs, or the release bearing isn’t moving freely. Check that the clutch fork moves smoothly and the hydraulic system is properly bled. If you used the wrong kit for your car, the pressure plate might be too aggressive. Always match the kit to your vehicle’s specs-not your driving fantasies.

How long should a clutch kit last?

A standard OEM clutch kit lasts between 80,000 and 150,000 km. Performance clutches with metallic discs may only last 40,000 to 60,000 km if driven aggressively. Driving style matters more than brand. Constant riding the clutch, hill starts in first gear, or frequent towing will wear it out faster. If your clutch fails before 60,000 km, check if you used the right kit and installed it properly.

Write a comment