Clutch Kit Checklist Tool

Is Your Clutch Kit Complete?

This tool verifies if your clutch kit contains all essential components. Missing critical parts can cause transmission failure or premature clutch wear.

Essential Components

The heavy steel component that clamps the clutch disc

The friction disc that transfers engine power

The bearing that disengages the clutch

Supports transmission input shaft (critical for proper alignment)

Essential for correct disc installation (not installed but required)

Torque-specific bolts for pressure plate installation

Optional Components

Connects release bearing to hydraulic system (not always included)

Reduces engine vibration (sometimes included)

Performance-oriented parts (e.g., ceramic discs)

Your Clutch Kit is Complete

All critical components are included. Proceed with installation.

When your clutch starts slipping, grinding, or feels spongy, you know it’s time for a replacement. But before you buy a new clutch kit, you need to know what’s actually inside it. A full clutch kit isn’t just a disc and a pressure plate-it’s a system of parts that work together to transfer engine power to the wheels. Skip understanding the pieces, and you risk installing something incomplete, which can lead to premature failure or even damage to your transmission.

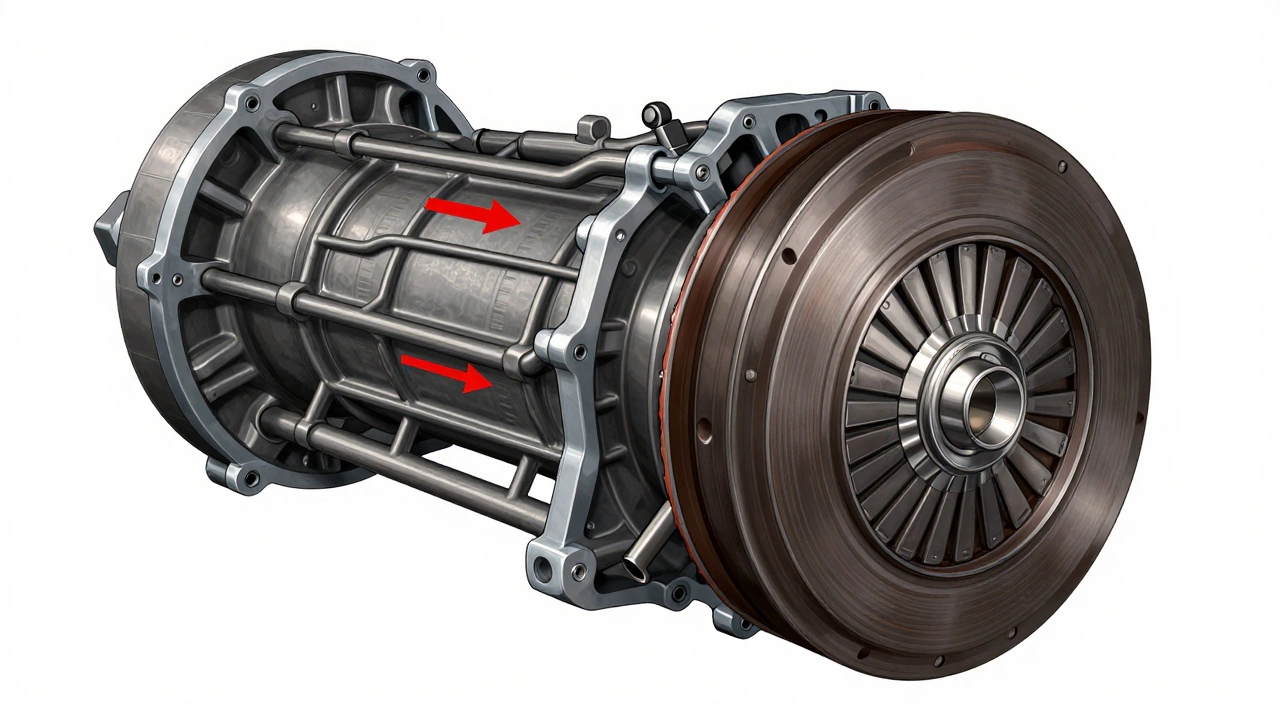

The Pressure Plate

The pressure plate is the heavy steel component bolted directly to the flywheel. Its job is to clamp the clutch disc against the flywheel using spring force. When you press the clutch pedal, the release bearing pushes against the pressure plate’s diaphragm springs, releasing that clamping force and disengaging the engine from the transmission.

There are two main types: diaphragm spring (most common in modern cars) and coil spring (older designs). Diaphragm spring pressure plates are more reliable, require less pedal effort, and last longer. If you’re replacing your clutch, always match the type-mixing parts can cause uneven wear or engagement issues.

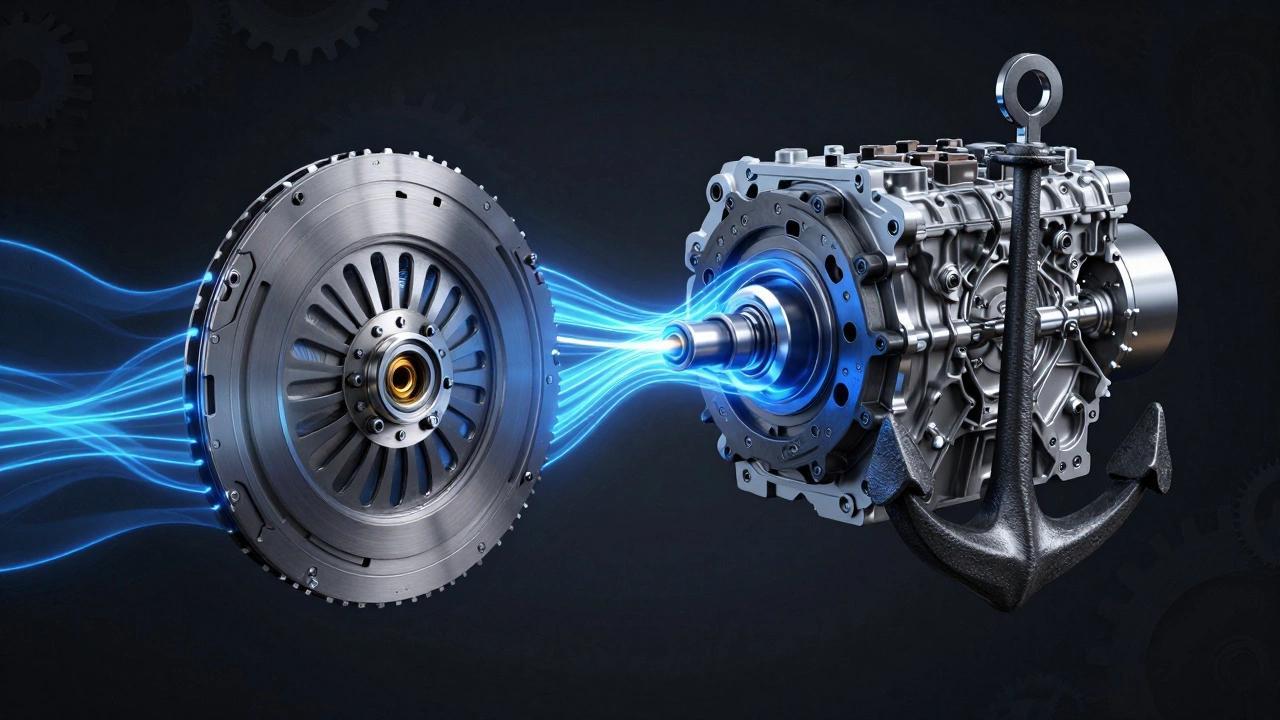

The Clutch Disc (Friction Disc)

This is the heart of the clutch system. It’s a round metal plate with friction material bonded to both sides, similar to brake pads. One side faces the flywheel, the other faces the pressure plate. When engaged, the friction material grips both surfaces, creating the connection that spins the transmission input shaft.

Clutch discs come in different materials: organic (smooth, quiet, for daily driving), ceramic (more heat-resistant, used in performance cars), and metallic (aggressive, used in racing). Most factory replacements use organic material because it’s durable enough for normal use and won’t wear out your flywheel too fast. If you’re towing or driving aggressively, you might need a ceramic disc-but don’t upgrade unless you know why.

The Release Bearing (Throw-Out Bearing)

This small, cylindrical bearing sits between the pressure plate’s diaphragm springs and the clutch fork. When you press the pedal, the clutch fork pushes the release bearing forward, which then presses against the springs to disengage the clutch. It spins constantly when the clutch is engaged and stops when disengaged.

It’s one of the most overlooked parts during replacement. A worn release bearing makes a grinding or whining noise when the pedal is pressed. If you don’t replace it when doing a clutch job, it’ll fail within 10,000 km-and you’ll be back in the shop. Always install a new one. They’re cheap, and the labor to access them is already done.

The Pilot Bearing or Bushing

This tiny part sits in the center of the flywheel and supports the transmission’s input shaft. It keeps the shaft centered while the clutch is disengaged. Without it, the shaft wobbles, causing vibration, noise, or even gear grinding.

Some cars use a ball bearing (pilot bearing), others use a bronze or nylon bushing. You can’t tell just by looking-you need to check your vehicle’s service manual. If the pilot bearing is worn, the input shaft will have play. Replacing it requires pulling the transmission, so it’s smart to do it while you’re already in there. Most full clutch kits include this part now, but always double-check the box before you start.

The Clutch Alignment Tool

It’s not a part you install, but it’s essential. A clutch alignment tool is a metal rod that fits into the center of the clutch disc and slides into the pilot bearing. It holds the disc perfectly centered while you bolt the pressure plate down.

If you skip this, the clutch disc can tilt during installation. That leads to uneven pressure, vibration, and premature wear. You can buy one for under $20, or sometimes the kit comes with it. Never try to align it by eye. Even a 1mm misalignment causes problems.

The Clutch Fork and Release Lever (Sometimes Included)

Not all kits include these, but they’re part of the clutch system. The clutch fork is the metal arm that connects the release bearing to the hydraulic cylinder or cable. The release lever is the pivot point it rotates on.

If you hear a clicking noise when pressing the pedal, or if the clutch feels stiff or inconsistent, the fork or lever might be worn. These parts don’t always fail at the same time as the clutch, but if your car has over 150,000 km, it’s worth inspecting them. Some aftermarket kits include upgraded steel forks for better durability.

Hardware: Bolts, Washers, and Springs

It sounds simple, but the bolts that hold the pressure plate to the flywheel are torque-sensitive. Reusing old ones can lead to warping or failure. Most full kits include new high-tensile bolts with the correct torque specs printed on the packaging.

Some pressure plates also have internal springs or dampeners that help reduce engine vibration. These aren’t visible unless you take the clutch apart, but they’re critical for smooth operation. Always use the hardware provided with the kit. Don’t grab random bolts from the toolbox.

What’s Missing From Cheap Kits?

Low-cost clutch kits often leave out the pilot bearing, alignment tool, or hardware. Others use low-grade friction material that wears out in 30,000 km instead of 80,000. Some even reuse the same pressure plate springs from old stock-meaning they’re already fatigued.

Stick with reputable brands like Sachs, Luk, Valeo, or Exedy. They test their kits to OEM standards. A $300 kit from a brand you’ve never heard of might save you $100 upfront, but if it fails in six months, you’ll pay double in labor and downtime.

How to Know If You Need a Full Kit

You don’t always need to replace everything. If your clutch disc is worn but the pressure plate still has even spring tension and no cracks, you might get away with just the disc and bearing. But here’s the catch: once you pull the transmission, you’re already paying for 3-4 hours of labor. Adding a few extra parts costs $50 and saves you a second visit.

Signs you need a full kit:

- Clutch slipping under load (especially uphill or towing)

- Grinding noise when shifting, even with the pedal fully pressed

- Clutch pedal feels softer or travels farther than before

- Fluid leaks from the clutch master or slave cylinder (indicates hydraulic system issues)

- More than 100,000 km on the original clutch

If you’re unsure, have a mechanic inspect the clutch components before you buy anything. A quick peek through the inspection hole can show you if the friction material is still thick enough.

What Happens If You Skip a Part?

Skipping the pilot bearing? The input shaft wobbles. That causes gear noise, synchro damage, and eventually transmission failure.

Reusing old bolts? They stretch. The pressure plate doesn’t clamp evenly. The clutch slips, overheats, and burns out the disc faster.

Not using an alignment tool? The disc is crooked. One side wears out in 5,000 km. You’ll hear a rhythmic clunk every time you let the clutch out.

These aren’t theoretical risks. I’ve seen three cars in the last year come back with the same problem: someone saved $40 on a pilot bearing-and ended up needing a $2,200 transmission rebuild.

Final Checklist Before You Install

- Full clutch kit includes: pressure plate, clutch disc, release bearing, pilot bearing, hardware

- Alignment tool is included or you’ve bought one separately

- All parts match your vehicle’s year, make, model, and engine

- You’ve checked the flywheel for warping or scoring-resurfacing may be needed

- You’ve got the correct torque specs for the pressure plate bolts

Installing a clutch is one of the most satisfying repairs you can do yourself-if you do it right. But it’s also one of the most unforgiving. One missing part, one wrong bolt, one misaligned disc, and you’re looking at a costly mistake. Take the time to understand what’s in the box. It’s not just parts. It’s the connection between your engine and your wheels.

Write a comment